Our commitment to sustainability goes beyond compliance — it's built into who we are. From water conservation and clean energy to community initiatives, every action reflects our belief in responsible progress.

Goodwear prioritizes water recycling through an architectural design that channels all wastewater back for reuse, cutting consumption well below industry averages.

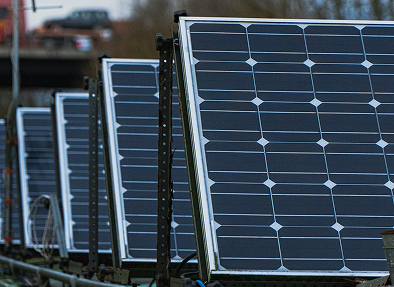

Innovative measures include the upcoming rotary brush cleaning system for solar panels, expected to reduce water use by 80%, and the adoption of dope-dyed yarns — a process that adds color to melted polyester chips before extrusion, eliminating traditional water-heavy dyeing.

Our facilities use bag filters and water scrubbers to keep air emissions below 50 ppm, significantly under the legal standard of 150 ppm.

This precision-driven control ensures clean operations and a safer working environment.

To minimize our carbon footprint, Goodwear has transitioned to PNG (Piped Natural Gas) and briquette-based fuel systems, reducing reliance on conventional fossil fuels

Every process is continuously evaluated to lower emissions and enhance efficiency.

Sustainability at Goodwear isn't a trend or an export-driven obligation — it's a foundational principle guiding how we think, build, and improve.

Our teams consistently strive to raise our Higg FEM audit scores, refine processes, and adopt cleaner, smarter manufacturing methods year after year.

Beyond factories and materials, Goodwear invests in people.Through education-focused initiatives, we repair schools, promote football programs, and conduct English education and confidence-building workshops — including our ongoing efforts in Ranchi School.

These projects reflect our belief that true sustainability starts with empowered communities.

Built on decades of experience and driven by continuous improvement, Goodwear's sustainability journey is a living commitment to future generations.